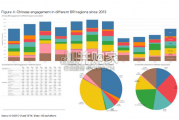

China’s financing and investment spread across 61 BRI countries in 2023 (up...

2024-02-27 31 英文报告下载

Global demand for defoamers stood at 2,550 kilo tons in 2014 and is anticipated to reach 3,550 kilo tons in 2023, increasing at a CAGR of 3.8% from 2015 to 2023. In terms of revenue, the defoamers market was valued at US$ 2,764 Mn in 2014 and is projected to reach US$ 4,107.5 Mn in 2023, expanding at a CAGR of 4.5% from 2015 to 2023.The global defoamers market is primarily driven by increasing demand for defoamers in pulp and paper, water treatment, and paints and coatings industries. However, factors such as regulatory issues are hampering market growth. Currently, alternative manufacturers focus on product innovation and customized solutions to increase their market share. Furthermore, growth in the emerging economies is expected to act as an opportunity for the defoamers market in the next nine years.

Silicone-based defoamers was the largest product segment of the global defoamers market in 2014, accounting for 44.6% share in 2014. Water-based defoamers is anticipated to be the fastest-growing product segment of the defoamers market, expanding at a CAGR of 4.1% from 2015 to 2023. Rising demand for defoamers in pulp and paper, paints and coatings, and water treatment industries is likely to drive the global defoamers market in the next few years. Pulp and paper was the largest application segment of the global defoamers market in 2014, holding 31.3% share in 2014. Water treatment is estimated to be the fastest-growing application segment of the defoamers market, expanding at a CAGR of 4.0% from 2015 to 2023. The global market for defoamers is highly fragmented in nature. The top five companies account for 18% share of the market in 2014. Key players in the defoamers market include Dow Corning Corporation, Ashland, Inc., Evonik Industries AG, Air Products and Chemicals, Inc., and Bluestar Silicones.

Foam, a bubbly liquid, is often produced as an unwanted by-product during the manufacture of various substances. Foam poses difficulties to various industries such as chemicals, especially during the biochemical process. It hampers the flow of liquid and blocks transfer of oxygen from air. Therefore, antifoaming agents (defoamers) such as silicone oils are added to prevent the problem of foaming. Usage of chemical methods to control foam are not always preferred, especially in food and pharmaceutical industries, where the product quality is of vital importance. Mechanical methods are mostly preferred over chemical methods to prevent the formation of foam in these industries. Defoamers or antifoaming agents are chemical additives that reduce and hamper the formation of foam in industrial process. Defoamers are generally insoluble in the foaming medium and possess surface active properties. These offer low viscosity and spread rapidly on the foamy surface. This is one of the essential characteristics of defoamers. Defoamers have affinity to the air-liquid surface, where these threaten the foam lamellas. This results in rupture of air bubbles and breakdown of the surface foam.

标签: 英文报告下载

相关文章

China’s financing and investment spread across 61 BRI countries in 2023 (up...

2024-02-27 31 英文报告下载

Though the risk of AI leading to catastrophe or human extinction had...

2024-02-26 52 英文报告下载

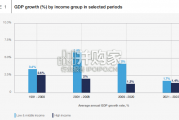

Focusing on the prospects for 2024, global growth is likely to come i...

2024-02-21 96 英文报告下载

Economic activity declined slightly on average, employment was roughly flat...

2024-02-07 67 英文报告下载

Economic growth can be defned as an increase in the quantity or quali...

2024-02-06 82 英文报告下载

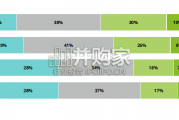

In this initial quarterly survey, 41% of leaders reported their organizatio...

2024-02-05 66 英文报告下载

最新留言